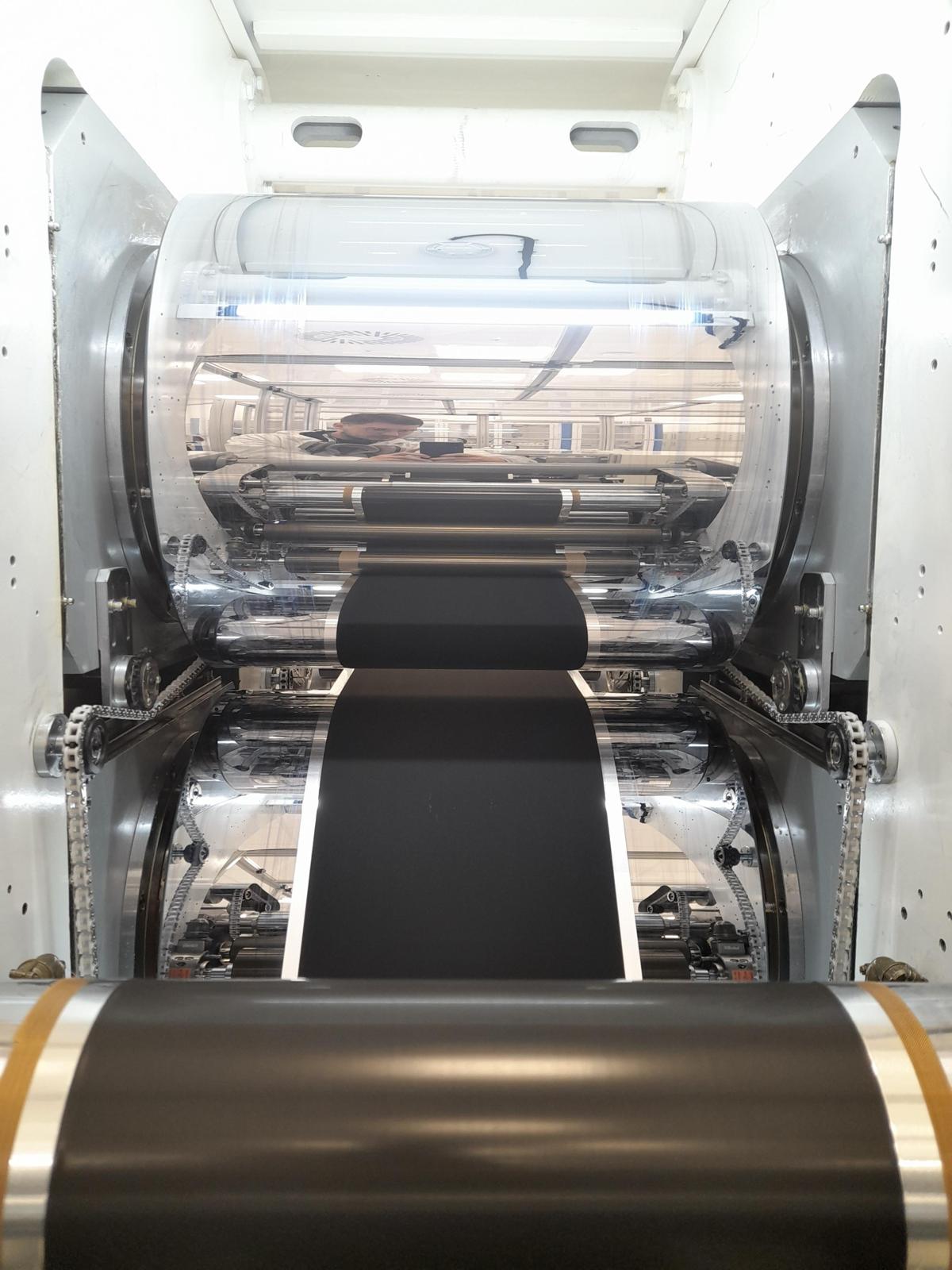

InoBat, a Slovak company dedicated to developing and manufacturing innovative batteries for electric vehicles, has announced another significant milestone. The first batteries labelled “made in Slovakia” have been successfully produced. Concurrently, the company has obtained all necessary certifications and initiated production of the first high-performance cells.

With the production launch in Voderady, Slovakia joins Sweden, Norway, Germany, and France as the fifth European country capable of producing certified battery cells with European know-how. Voderady serves as a vital catalyst for transitioning from a mere assembly plant to a center of innovation. “We not only manufacture batteries but also design and tailor them to meet each customer’s needs. This process requires exceptional knowledge and specialized skills, and I am proud that we have developed it in Slovakia,” emphasizes InoBat CEO, Marián Boček.

According to Patrick Križanský, Director of the Slovak Association for Electromobility, this marks another significant step towards transforming the automotive industry towards electromobility. “The Slovak automotive sector is a key player in the global market, and its transition to electromobility is necessary not only for environmental sustainability but also for preserving the competitiveness of our industry. InoBat is evidence that with favourable conditions and incentives for research and development, innovations competitive on a global scale can emerge in Slovakia,” adds Križanský.

In recent months, InoBat has also expanded its personnel. Dozens of operators and maintenance technicians from Slovakia have joined the production, necessitating their requalification due to the modern and advanced technologies involved. Currently, the company employs an international team of experts from 18 countries worldwide. The combination of direct experience with battery technology and local talent has enabled the creation of the first requalification course in Slovakia, laying the foundation for a new profession – battery cell production operator.

“The preparation for the production of our products involves not only careful adjustment of technological processes and production lines but also ensuring an adequate supply of qualified personnel. We aim to educate top-notch experts and professionals and provide opportunities for those who have worked in similar segments. We intend to create a team that is not only competitive in the market but also capable of presenting revolutionary and innovative products to our customers,” explains InoBat CEO Marián Boček.

InoBat initially requalified its workers within the existing research and development center in Voderady, where a pilot battery production line is located. The requalification process itself is divided into three main parts: theoretical training, technical training, and on-the-job training. The educational program has been developed in-house and tailored to the company’s needs, combining the expertise of InoBat employees with engineers from the Chinese company Wuxi Lead, the supplier of the production line.

The education of employees at InoBat has also been praised by Andrej Hutta, Chairman of the Employers’ Board for Vocational Education and Training (Rada zamestnávateľov pre odborné vzdelávanie a prípravu), who emphasized that “the demand for technically educated graduates and the labor market’s requirements for the qualified workforce have been consistently high. It is therefore essential to maintain the continuity of vocational education and the ability to adapt to new technological processes. The field of electromobility offers enormous opportunities. It is a sector where more people will be employed in the future. The emergence of a new highly specialized profession in Slovakia is of immense added value.”

The established educational and requalification processes are planned to be implemented in the planned gigafactory in Šurany, a joint project of InoBat and the Chinese company Gotion High-Tech (GIB – Gotion InoBat Batteries). Together, they aspire to build the most advanced battery factory in Šurany with a zero carbon footprint not only in Europe but also globally. GIB estimates that more than 1500 employees will work in the factory, the majority of whom will require requalification or professional vocational education.

About InoBat:

InoBat specializes in the research, development, design, manufacturing, supply, and recycling of innovative electric batteries tailored to meet the specific range and requirements of global original equipment manufacturers (OEMs) and energy sector participants. It focuses on the automotive, commercial vehicles, motorsport, and aerospace industries, providing innovative solutions across the entire value chain through its “C2C” (cradle-to-cradle) approach. InoBat is supported by a strong consortium of strategic investors and partners, including Rio Tinto, Gotion, Amara Raja, Lilium, International Finance Corporation (IFC), Slovak Investment Holding (SIH), and original sponsors IPM Group, Avanea, and Across. InoBat has received financial support for research and development through EU-sponsored programs, important projects for common European interest (IPCEI), and additional support from the Slovak government.

GIB represents the joint efforts of InoBat and Gotion High Tech in building a gigafactory for batteries in Slovakia. It is a unique example of a strong partnership between a rapidly growing startup with cutting-edge project development experience and knowledge of the Slovak context and a technological leader capable of providing the full range of technology and manufacturing capacity to increase production. Gotion High-Tech is the world’s third-largest battery supplier with a production capacity of 100 GWh across 14 gigafactories in Asia. Their 15th and first European gigafactory is planned in Šurany, Slovakia in partnership with InoBat.